Exploring the possibilities of plastic

Swinburne’s Polymer Lab is a cutting-edge research hub for polymer manufacturing, processing and analysis. Here, engineering students get hands-on experience in polymer and material processing and performance evaluation. Research projects range from investigations into 3D printing and robotics for repairing equipment, to recycled plastics for bedding. With a focus on circular product design and sustainable principles for the circular economy, here, students gain real-world skills for a next-gen engineering career.

On this page you'll find:

Explore the lab

With a range of manufacturing and analysis equipment, the Polymer Lab allows for dedicated sustainability research into recycled materials, plastics and polymers

-

Student using the APSX-PIM Plastic Injection Moulding Machine to create a test specimen.

Student using the APSX-PIM Plastic Injection Moulding Machine to create a test specimen. -

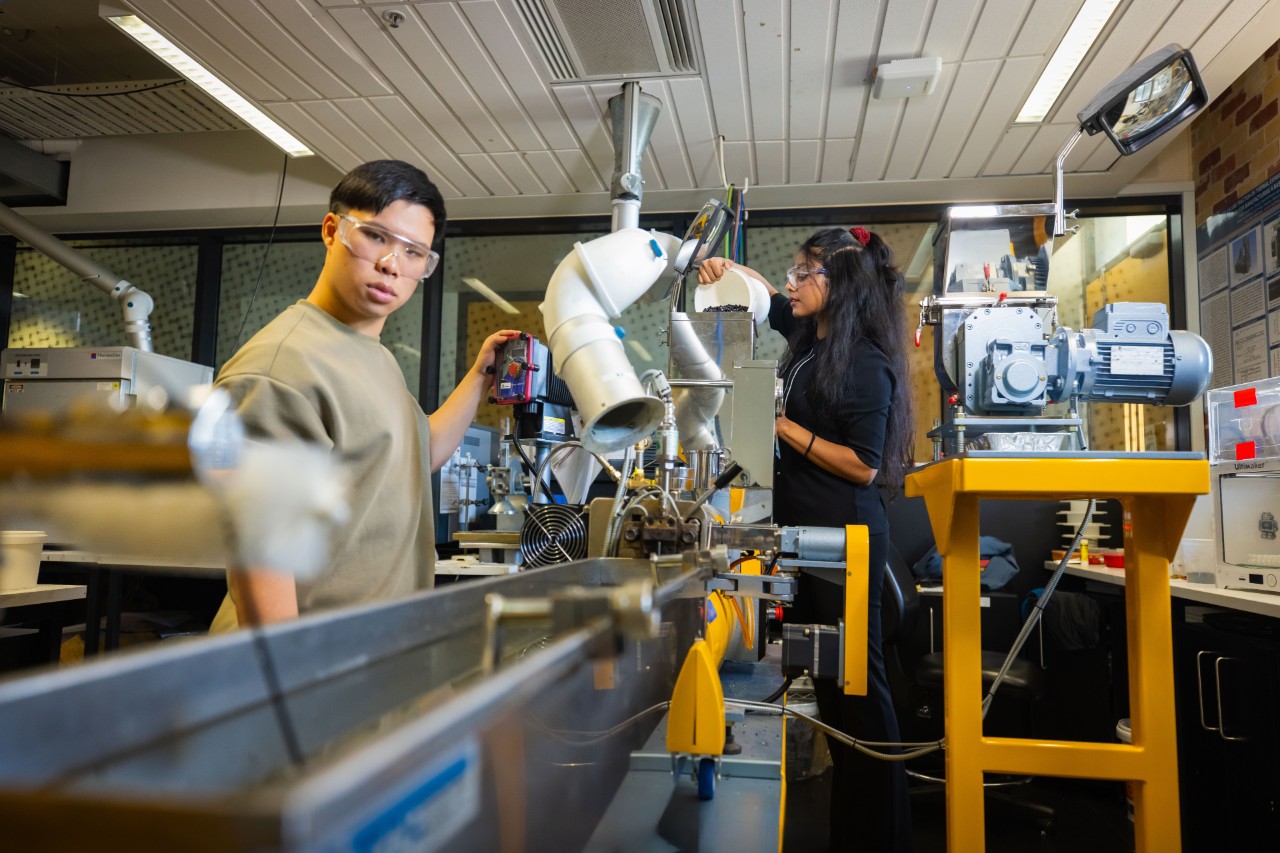

Students using the LabTech LTE16-40 Twin screw extruder to manufacture versatile polymer profiles

Students using the LabTech LTE16-40 Twin screw extruder to manufacture versatile polymer profiles -

Students using the INSTRON-CEAST Pendulum Impact Testing Machine to determine a material’s impact resilience .

Students using the INSTRON-CEAST Pendulum Impact Testing Machine to determine a material’s impact resilience .

Using the lab

The Polymer Lab is home to the new frontier of innovation in material science. Undergraduate and postgraduate students use the lab alongside industry, with applications ranging from automotive to mining, aerospace, construction materials and more. The lab is available for external hire, to support research in manufacturing, composites and thermoplastics.

Companies and Researchers

Ready to test a new product, but don’t have the facilities? With access to Swinburne’s Polymer Lab, you’ll be able to use our equipment to determine a material’s tensile strength, flexibility and toughness, or explore novel manufacturing avenues.

Students and Staff

Third year Mechanical and Product Design Engineering students will make use of the lab’s equipment in Manufacturing units, as will students completing final year capstone projects related to product analysis and manufacturing.

-

A student operating the Fused Filament Fabrication (FFF) 3D Printer.

A student operating the Fused Filament Fabrication (FFF) 3D Printer. -

A student using the PolyJet EDEN350 3D printer.

A student using the PolyJet EDEN350 3D printer. -

A student using the Zwich Z010 Universal Testing Machine to evaluate a material’s mechanical properties.

A student using the Zwich Z010 Universal Testing Machine to evaluate a material’s mechanical properties.

Related courses

-

Bachelor of Engineering (Honours)

75.0

Guaranteed Entry ATAR or more entry options4 years full-time or equivalent part-time 4 years full-timeHawthornSemester 2Semester 1Choose your major

Architectural

This major combines structural and environmental building engineering with architectural creativity. You'll be creating the buildings of tomorrow in both on-site class and unique industry placements.

Biomedical

Learn to improve health care and quality of life through the application of electrical, electronics and systems engineering in medicine and biology.

Civil

Build the future – literally – with a Swinburne civil major, featuring technical excellence and a host of real-world industry learning opportunities.

Electrical and Electronic

Gain technical expertise in power system design, electronics, control systems, signal processing and embedded systems.

Mechanical

Learn the core concepts of mechanics, kinematics, thermodynamics, fluid mechanics and energy as you participate in industry-based projects and practical workshops.

Product Design

The product design major combines the creativity and human-centred approach of industrial design with the academic rigour of engineering science and innovation.

Robotics and Mechatronics

Discover three traditional engineering disciplines – mechanical, electronics and software – as you bolster your CV with real industry experiences.

Software

Dive into a career in advanced software engineering with an emphasis on teamwork, problem solving and practical software engineering skills.

-

Master of Engineering Science

2 years full-time or equivalent part-time 2 years full-timeHawthornHawthornSemester 2Semester 1Full-time, Part-time Full-timeChoose your specialisation

Advanced Manufacturing

The advanced manufacturing specialisation gives you the skills to ensure quality, efficiency and productivity in manufacturing environments.

Civil Engineering

The Civil Engineering Specialisation will give you the skills and knowledge to ensure the safe, efficient, and sustainable development of physical infrastructure

Electrical Engineering

The Electrical Engineering specialisation equips students with the core skills to design, develop and innovative electrical systems and technologies

Electronics and Telecommunications Engineering

Gain expertise in power systems, digital circuits, and electronic devices with the Electronics and Telecommunications Engineering specialisation.

Mechanical Engineering

Learn the core concepts of surface engineering, industry 4.0, computer modelling and fluid mechanics as you participate in industry-based projects and practical workshops.

Structural Engineering

Our Structural Engineering Specialisation prepares you with the skills and knowledge necessary to design, analyse, and construct various structures.

Contact us

If you’re a PhD student, a professional or an organisation looking to partner with us or access our facility, please contact Professor Mostafa Nikzad: mnikzad@swin.edu.au

Equipment

Swinburne’s Polymer Lab houses specialised equipment for material processing, characterisation and performance evaluation.

- 3D printing, including FFF, DLP, PolyJet and HP Jet Fusion 3D printers

- Dynamic Mechanical Analyser (DMA)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

- Melt Flow Index test (MFI)

- Atomic Force Microscopy (AFM) and Nanoindentation

- SEM and XRD, SPX, Raman and Fourier-Transform Infrared (FTIR)

- Ultrasonic Testing

- Radio Frequency Testing

- Micro-CT

- Synchrotron facilities

- Twin screw extruder

- Plastic Injection Moulding Machine

- Pendulum Impact Testing Machine

- Universal Testing Machine

- Scientific Hydraulic Press

Partner with us

Contact us to gain access to the Polymer Lab’s material testing facilities, collaborate with Swinburne researchers or work with engineering undergraduate and postgraduate students through industry-linked projects.

Location and contact

ATC 801 , Hawthorn campus

Associate Professor Mostafa Nikzad, mnikzad@swin.edu.au