From waste to walls: how your morning coffee can supercharge sustainable construction

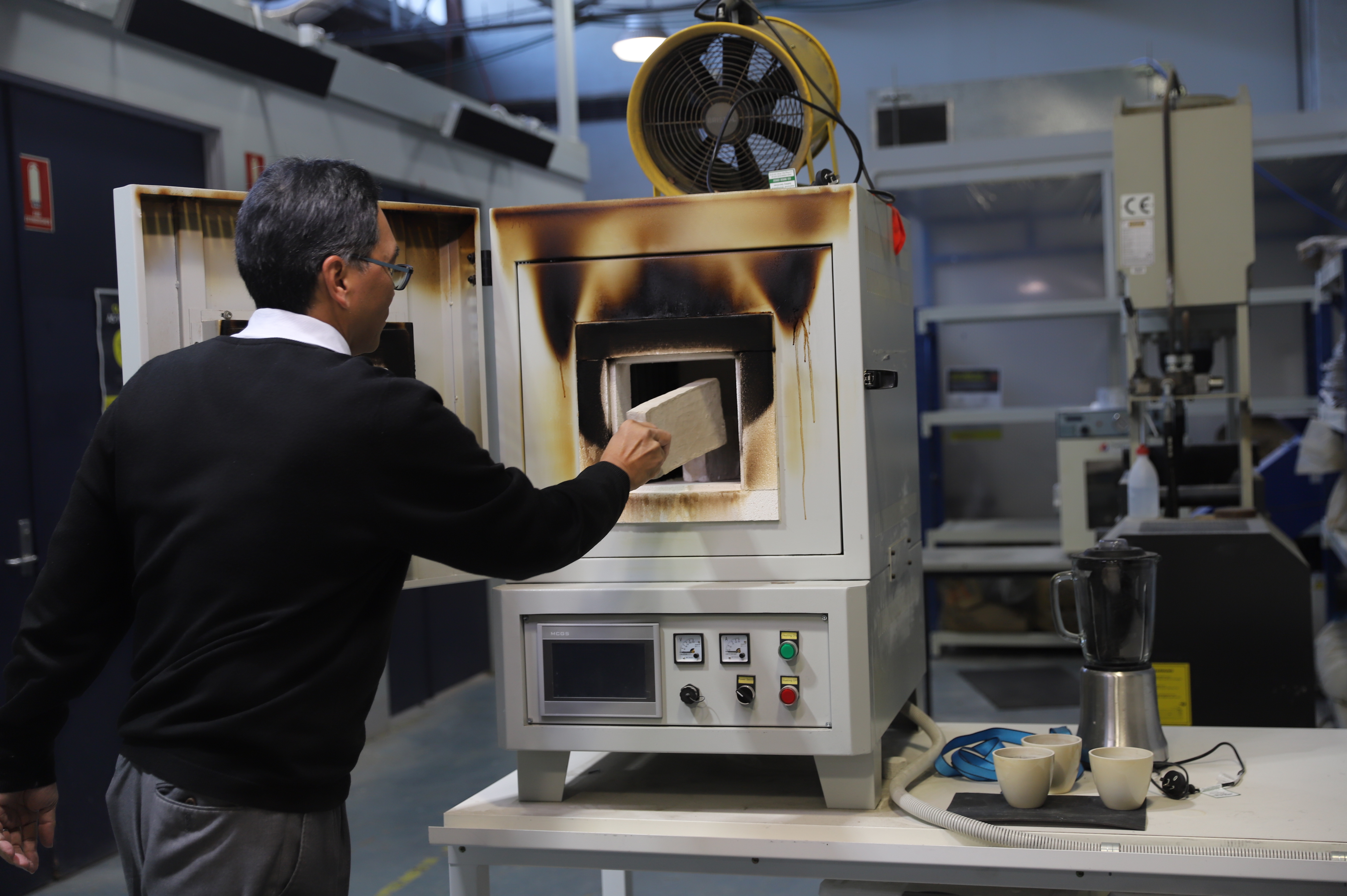

Swinburne's Dr Yat Wong firing bricks made from coffee waste

In summary

- Swinburne’s Dr Yat Wong has invented a sustainable brick made from coffee waste

- The product has landed an IP licensing deal with Green Brick to bring the product to market

- The brick could reshape Australia’s construction industry by lowering its carbon footprint

Bricks made from used coffee grounds could soon reshape Australia’s construction industry, and its carbon footprint, thanks to researchers at Swinburne University of Technology.

Led by Dr Yat Wong, the project has now reached a commercial milestone: an IP licensing deal with Green Brick to bring the product to market with the support of Hampton Capital. The low-emission bricks are made by blending used coffee waste from cafes and restaurants with clay, then adding an alkali activator. This process allows the bricks to be baked at temperatures below 400 degrees Celsius, 80 per cent lower than traditional firing temperatures.

“It’s lighter on energy, faster to produce, and designed to reduce electricity-related CO₂ emissions by up to 80 per cent per unit,” Dr Wong said.

Dr Yat Wong

Traditional brick manufacturing is energy-intensive and relies heavily on high-temperature kilns powered by fossil fuels. By contrast, this new method dramatically lowers the environmental toll, providing a sustainable alternative for an industry under increasing pressure to decarbonise.

Sustainability isn’t the only benefit: the bricks double the Australian minimum standard for strength.

Green Brick’s founder, Philip Ng, says it’s not just about disrupting the brick, it’s about redefining how construction materials are valued in a net-zero economy.

“For the last century, materials have been judged by one thing: cost per square metre, but in the next chapter, we’ll judge them by carbon, transparency, and circularity. And those metrics favour a whole new kind of product,” Ng says.

Coffee consumption in Australia is booming, with over 1.3 million cups sold every day, generating roughly 10,000 tonnes of spent coffee grounds each year. Most of that waste ends up in landfill, where it emits methane, a potent greenhouse gas. Redirecting that waste stream into a valuable building product offers a dual environmental benefit: reducing both landfill and emissions.

-

Media Enquiries

Related articles

-

- Astronomy

- Technology

- Health

- Science

- University

- Sustainability

- Engineering

Swinburne highly cited researchers reach the top in 12 fields

Ten Swinburne academics have been named on the Highly Cited Researchers 2025 list, released by Clarivate

Tuesday 02 December 2025 -

- Science

- Engineering

Swinburne secures grant to advance next-generation metamaterials research

Swinburne physicist Dr Weibai Li has received a Discovery Early Career Researcher Award from the Australian Research Council

Tuesday 02 December 2025 -

- University

Over 550 students don caps and gowns to graduate from Children’s University Swinburne

Over 550 students from 34 schools have graduated from Children’s University Swinburne, celebrating over 45,000 hours of learning beyond the classroom this year.

Wednesday 03 December 2025 -

- Technology

- Health

- Science

- University

$1.2m ARC funding to boost national X-ray spectroscopy capability through Swinburne and QUT partnership

Swinburne has secured $1.2 million in the latest Australian Research Council Linkage Infrastructure, Equipment and Facilities scheme round

Tuesday 02 December 2025 -

- University

Swinburne researchers shine at the 2025 Media and External Communications Recognition Awards

Swinburne’s 2025 Media and External Communications Recognition Awards have recognised our academics for notable media and social media outreach.

Thursday 04 December 2025